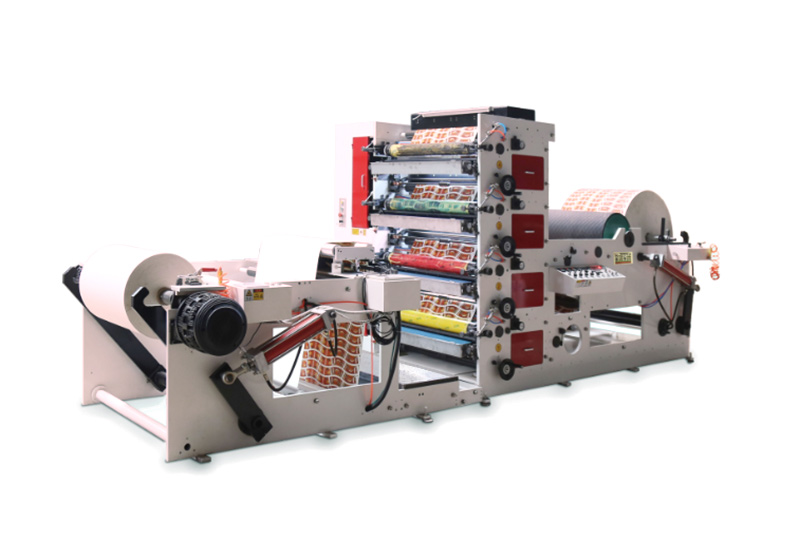

KBB100 Roll to Roll Flexo Printing Machine

Paper Cup Flexo Printing Machine

Offers flexo printing capability on paper rolls for producing up to 5 million paper cups per day.

- Flexo printing machine is an essential and indispensable piece of modern printing equipment used in the paper cup and various paper-based industries.

- The ceramic anilox roller, one of the main components, plays a critical role in the printing process with its high performance. Made from advanced ceramic materials, this anilox roller ensures excellent print quality for many years. At the same time, improvements in wear resistance, corrosion resistance, and thermal stability significantly extend its service life. Thanks to its easy cleaning feature, you can use it for months without removing it from the machine. This allows continuous flexo printing throughout the day without stopping your workflow.

- Since our flexo printing machine operates roll-to-roll, edge control is essential for stable production. For this reason, our machine is equipped with an edge control (EPC) system. This system ensures smooth paper feeding even if the paper rolls are not perfectly aligned. As a result, the rolls wind evenly and properly. During cutting, your raw material production continues with minimal issues.

- Our industrial-grade paper cup flexo printing machine enables printing on paper cup sheets, paper boxes, paper bowls, and other paper-based products. In many sectors, you can perform roll-to-roll printing.

- Designed for uninterrupted operation, our machine can continue working 24/7 without the need for downtime, except for periodic cleaning breaks. It can provide service without shutting down throughout the day. With a daily capacity of nearly one truckload, it ensures high efficiency. Using standard 6oz 150gr raw material, it is possible to print up to 5 million paper cups in 24 hours.

Roll-to-Roll Flexo Printing Machine

Long-term efficiency without the need for revisions

99%

0–80 m/min

Printing Speed

120 cm

Unwinding Width

96 cm

Rewinding Width

20 tons

maximum daily print capacity

Features

Corrects Misaligned Rolls and Provides More Stable Rewinding

EPC Edge Control System

Offers high printing quality and long durability

Ceramic Anilox

Its geared structure and technology allow seamless production of cup sidewall paper

Seamless Printing Capability

Practical ink chamber and print control mechanism

Printing Unit

Hydraulic lifters and Pneumatic Brake System

Unwinding and Braking

Stable tension winding with automatic tension control and minimal error

Rewinding Unit

Optional Features

Reduces Cup Adhesion Issues

Corona Treatment

Enables Image Capture at High-Speed Printing

Flexo Printing Camera

Provides Higher Quality and Sharper Printing

UV Drying

KBB100 Paper Cup Printing Machine

Flexo Printing Machine

Technical Specificationsr

| Model | KBB100 |

| Print Repeat Length | 255mm – 620mm (81T – 195T) |

| Max. Web Width | 96 cm |

| Max. Printing Width | 95 cm |

| Power Consumption | 30 kW |

| Electrical Requirements | 380V 3PH 50Hz |

| Machine Speed | 0–80 m/min |

| Printing Plate Thickness | 1.7 mm |

| Double-Sided Plate Mounting Tape Thickness | 0.38 mm |

| Printing Accuracy | ±0.15 mm |

| Pneumatic Air Shaft | 3 inch |