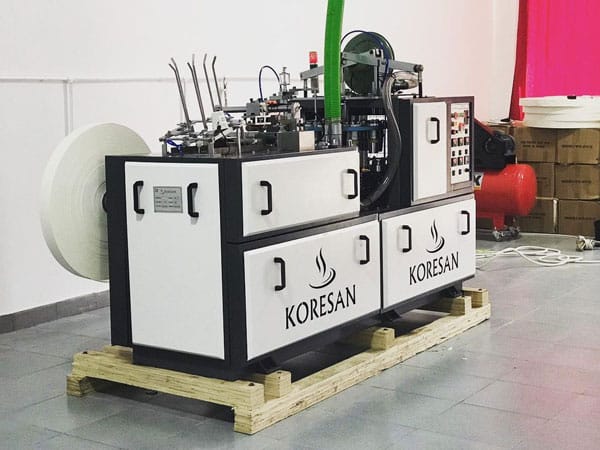

Paper Cup Machine

Production Speed: 80–120 cups per minute

- Thanks to its compact dimensions, 6 units can fit into a 20-foot container and 12 units into a 40-foot container. This provides important logistical advantages, especially for our overseas customers.

- Thanks to its compact dimensions, 6 units can fit into a 20-foot container and 12 units into a 40-foot container. This provides important logistical advantages, especially for our overseas customers.

- Despite competing with market prices, our high-speed KRC120 paper cup machine operates up to twice as fast as many competitors. With a maximum speed of 120 cups per minute, the KRC120 model ensures a stable and consistent performance at 110 cups per minute.

- Featuring an open-cam system, the KRC120 model has a more durable structure and is much easier to maintain compared to chain-type models. The enlarged cam area is specifically designed to provide easier operation and maintenance access.

Our automatic lubrication system is more advanced than ever. In older closed-cam models, operators needed to perform lubrication at each shift. In this model, the entire cam mechanism is now fully automatically lubricated, allowing you to run the machine efficiently with minimal operator intervention.

If desired, you may choose the ultrasonic sealing option for your paper cup machine. The video shows the production of 5oz vending paper cups. Since vending cups are more sensitive and produced with higher grammage paper, ultrasonic sealing is preferred for stronger bonding.

FULLY AUTOMATIC – FULL OPTION

The KRC120 Plus model is mechanically the same as our KRC120 machine; however, it has been upgraded with additional components to enable the production of higher grammage cups. Thanks to its ultrasonic and hot-air heating systems, it provides ease of use for paper cups up to 350 gsm. In addition, the PLC touch screen and bottom paper conveyor offer enhanced operational convenience.

With the remote control and PLC screen, you always have full control of the machine. In addition to its ease of use and operational practicality, the PLC system also manages the cooling of the hot-air heating resistances used in the bottom-sealing process. Even when the machine is shut down, the PLC keeps the fans running for an additional 5 minutes to cool the heating elements.

In paper cup machines, the most sensitive parts are always the ultrasonic units. Overcurrent or unstable voltage can cause serious damage and costly repairs. In the KRC120 Plus model, an overcurrent protection control panel is used to minimize malfunctions and extend the lifespan of ultrasonic components.

The hot-air sealing system minimizes leakage and ensures strong bonding even on thick and high-grammage papers. The PLC system also prevents the fan from stopping immediately when the machine is turned off. After the machine shuts down, the cooling process continues for another 5 minutes to protect the heating resistances.

Machine Technical Specifications

| Model | KRC120 |

| Production Capacity | 80–120 cups/min |

| Paper Cup Size | 3–9 oz (moulds can be changed within this range) |

| Raw Material (Resistance Heating) | 150–200 gsm single or double PE-coated paper |

| Raw Material (Ultrasonic + Hot Air) | 150–350 gsm single or double PE-coated paper |

| Electricity | 220V 50Hz 1-phase / 380V 50Hz 3-phase (3-month lead time for 220V option) |

| Power | 4 kW |

| Net Weight | 1300 kg |

| Dimensions | 2100 mm × 1100 mm × 1700 mm |

Free Installation and Training

At our Koresan factory in Gaziantep, we provide one week of free training. During this training, you will learn both basic maintenance and repair procedures, as well as detailed production processes.

Customer Services

You can benefit from our remote support services during business hours through our branches in South Korea, China, and Gaziantep. Our service locations are Istanbul, Ankara, Gaziantep, and Kilis.

Global Support

We supply machine spare parts and raw materials worldwide. We have regular monthly imports from Korea, Japan, China, and Finland. This allows us to provide all your needs quickly and cost-effectively.

Fransa Kervan Cup – 3. Sevkiyat 2 adet 4oz KRC120 ve KRC100 7oz Makine Kurulumu

Fransa Kervan Cup – 2. KRC120 Plus 7.5oz Makine Kurulumu