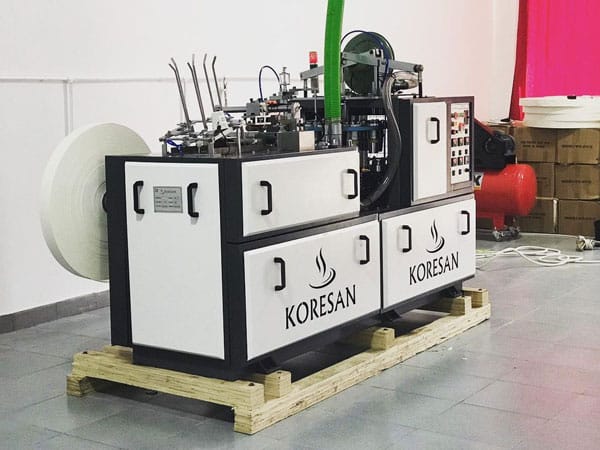

Paper Cup Machine

- 1. With its copper heating system, this paper cup machine is suitable for producing cups intended for hot beverages. It can process raw materials ranging from 140 gsm to 260 gsm. For higher grammage paper, an ultrasonic sealing system can be integrated.

- 2. The machine parts are manufactured using reinforced pressing techniques, making them 10 times stronger compared to those produced with traditional lathe machining methods.

- 3. Thanks to the retractable bottom paper blade, the bottom paper expands more easily and ensures a stronger sealing. This improves the heat resistance of the produced cups and enhances their durability during long-term use.

- 4. A special robot arm is used for collecting and rotating the cups. This significantly reduces working time and energy consumption.

Technical Specifications

| Model | KRC70 |

| Production Capacity | 60–70 pcs/min |

| Paper Cup Size | 2–9 oz |

| Raw Material (Resistance Heating) | 150–210 gsm, single-side PE coated |

| Raw Material (Ultrasonic) | 150–350 gsm, single-side PE coated |

| Electricity | 220V 50Hz Single Phase / 380V 50Hz Three Phase |

| Power | 4–5 KW |

| Net Weight | 1400 Kg |

| Dimensions | 2200 mm × 1000 mm × 1500 mm |

Free Installation & Training

At our Koresan factory in Gaziantep, we provide one week of free training, covering both basic maintenance and repairs as well as all production processes in detail.

Customer Services

You can benefit from our remote support services through our branches in South Korea, China, and Gaziantep during weekday business hours. Our service locations are in Istanbul, Ankara, Gaziantep, and Kilis.

Global Support

We supply your machine spare parts and raw materials from all around the world. We carry out regular monthly imports from South Korea, Japan, China, and Finland. This ensures that all your needs are met quickly and cost-effectively.

How Is Paper Cup Production Cost Calculated?

Determining Paper Cup Machine Size and Paper Grammage

You can easily calculate the cost of each cup size based on its grammage.

In this article, we will calculate the average cost for standard tea cup sizes between 5.7 oz – 7 oz.

On average, a 5.7 oz cup weighs approximately 3 grams.

From 1 ton of 5.7 oz paper, you can produce approximately 351,000 cups.

Bottom Paper Consumption and Cost

When producing average tea cup sizes on paper cup machines, bottom paper consumption is typically around 20%.

From a 1000 kg (1-ton) jumbo roll, approximately 200 kg of bottom paper will be used (around 357,000 cups × bottom paper cut pieces).

Note:

The example below is based on 5.7 oz die-cut numbers for the Koresan Cutting Machine.

Numbers may vary between manufacturers.

What Is the Total Paper Cost per Carton of Paper Cups?

1 ton of paper purchased:

1000 kg × 1.4 USD = 1400 USD + VAT

200 kg bottom paper:

200 kg × 1.4 USD = 280 USD + VAT

1 ton of side-wall paper we cut:

1000 kg × 0.09 USD = 90 USD + VAT

Total paper cost:

1400 USD + 280 USD + 90 USD = 1770 USD + VAT

Based on this calculation, we consumed a total of 1200 kg of paper.

From this paper, the average number of cups produced is 351,000 pcs.

1 shipping box (carton) in Turkey contains 3000 paper cups.

Thus:

351,000 / 3000 = 117 cartons of finished cups.

Paper Cost per Carton:

1770 USD / 117 cartons = 15.12 USD + VAT

Note:

VAT rate on paper cup raw materials in Turkey is 18%.

When purchasing a Paper Cup Machine, there are a few essential points you should pay attention to:

Determining the Cup Size

Determining Your Budget

Choosing the Paper Grammage and Quality

Understanding the Production Time

We have explained the reasons and details of these points in our article.

You can read the full content by clicking the link below.

To fully understand how paper cups are produced, you can watch the production facility video from South Korea at the link below.

This facility is one of the largest in South Korea. With more than 50 paper cup machines, all production stages are carried out in-house.

In most facilities in Turkey, production is usually carried out with 4–5 machines, while printing and die-cutting operations are done independently.

The KRC70 Paper Cup Machine can be ordered with different sealing methods.

If you prefer, you can equip your machine with ultrasonic side sealing.

With ultrasonic sealing, you can easily bond high-grammage paper without any issues.

Additionally, thanks to the ultrasonic system, our KRC70 Paper Cup Machine is capable of producing cup sizes ranging from 2 oz to 9 oz.